Engineering the Future of Industrial Automation

ABOUT US

We are a highly specialized engineering firm that transforms industrial

operational challenges into sustainable competitive advantages. As a strategic partner, we help facilities move beyond basic efficiency to

achieve greater agility, resilience, and predictive intelligence. Our robust automation solutions solve complex problems in the short

term while ensuring long-term operational viability and profitability.

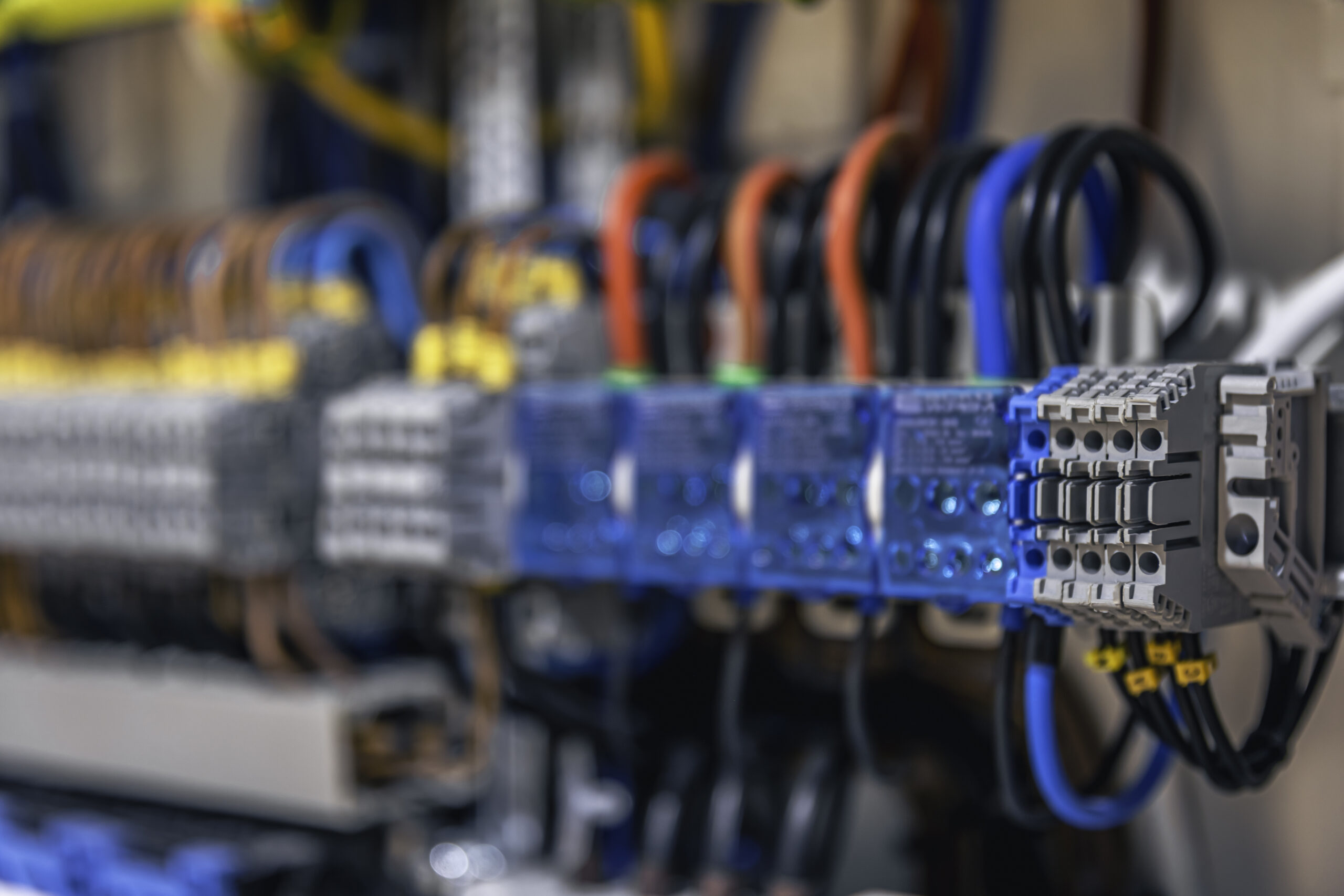

We integrate advanced automation, electrical, and industrial technologies with a multidisciplinary approach that bridges engineering expertise and real-world operations. By combining innovation with precision execution, we enable our clients to modernize assets, optimize processes, and unlock new levels of performance. Every project we deliver is tailored to specific operational needs, ensuring measurable results and lasting value.

OUR MISION

We are a solid engineering firm specializing in the design, execution, and maintenance of technological solutions in automation, electrical systems, construction, and industrial services. Our mission is to transform production processes through technically sound, client-tailored projects — driven by deep expertise, precision, and effective operational execution.

To be a leading engineering firm recognized for delivering innovative, reliable, and sustainable technological solutions in automation, electrical systems, construction, and industrial services.

OUR VISION

Our mission is to transform industrial production processes through technically sound, client-tailored projects — driven by expertise, precision, and efficient execution. Our mission is to become a leading company in the southern United States for the integration of complex industrial projects, recognized for our technical expertise, multidisciplinary approach, and innovative solutions.

We lead with strategic vision, delivering efficient services through a highly skilled team that drives client growth. We aim to build long-term partnerships based on measurable results, technical trust, and a consistent commitment to excellence.

“One of our defining characteristics is always being honest with our clients, telling them what’s technically feasible and what isn’t”

Julián Sánchez CEO

OUR EXPERTISE AREAS

Automation Architecture & Process Control

▸PLC/PAC control system design for discrete, continuous, and batch processes.

▸SCADA & HMI systems for centralized monitoring and control.

▸High-precision motion control & servo systems integration.

▸Machine safety systems, including safety-integrated desings compliant with global standards.

Asset Modernization & Lifecycle Management

▸Migration of obsolete platforms, such as Siemens S5 → TIA Portal, and Allen-Bradley PLC-5/SLC→ ControlLogix.

▸Industrial network upgrades, including DeviceNet/ControlNet → EtherNet/IP transitions.

▸Reverse engineering for undocumented or unsupported legacy systems critical to operation.

Industrial Intelligence & OT/IT Connectivity

▸Secure OT network architectures, based on Purdue Model and ISA/IEC 62443 standards.

▸Industrial IoT platforms for real-time data acquisition & contextualization at the plant level.

▸Vertical integration with MES and ERP systems to enable enterprise-wide visibility and control.

Robotics & Advanced Manufacturing

▸Integration of FANUC robotic cells for seamless HMI and system synergy.

▸Advanced robot programming for welding, palletizing and precision assembly.

▸Machine vision systems for Poka-Yoke and robot guidance.

PLATFORM MASTERY

We excel in mastering leading industrial platforms, ensuring seamless integration, optimal performance, and long-term operational reliability.

FEATURED PROJECTS

CENTERLINE WINSOR, CA

CHALLENGE: Launch of a new automotive production line integrating PLCs and FANUC robots, with strict cycle time requirements.

SOLUTION: Development of a standardized programming template and implementation of a robust communication protocol.

RESULT: ▸12% reduction in cycle time.

▸ Notable improvement in line OEE.

FORD MAVERICK CELL P758

CHALLENGE: Implementation of a new automotive production line integrating PLCs and FANUC robots, with tight cycle time constraints.

SOLUTION: Developed a standardized programming template and implemented a robust communication protocol between PLCs and robotic systems.

RESULT: ▸12% reduction in cycle time.

▸ Notable improvement in line OEE.

COLLABORATION MODEL

1.Technical Diagnosis & Root Cause Analysis

2. Architecture Design & Proof of Concept (PoC)

3. Implementation, Commissioning & Launch

4. Knowledge Transfer & Lifecycle Support

CONTACT US